A glimpse into the paint market in Norway in times of war

Preliminary results of an ongoing research project on painting materials in Norway during WW1 and post-war are presented in this text from a poster.

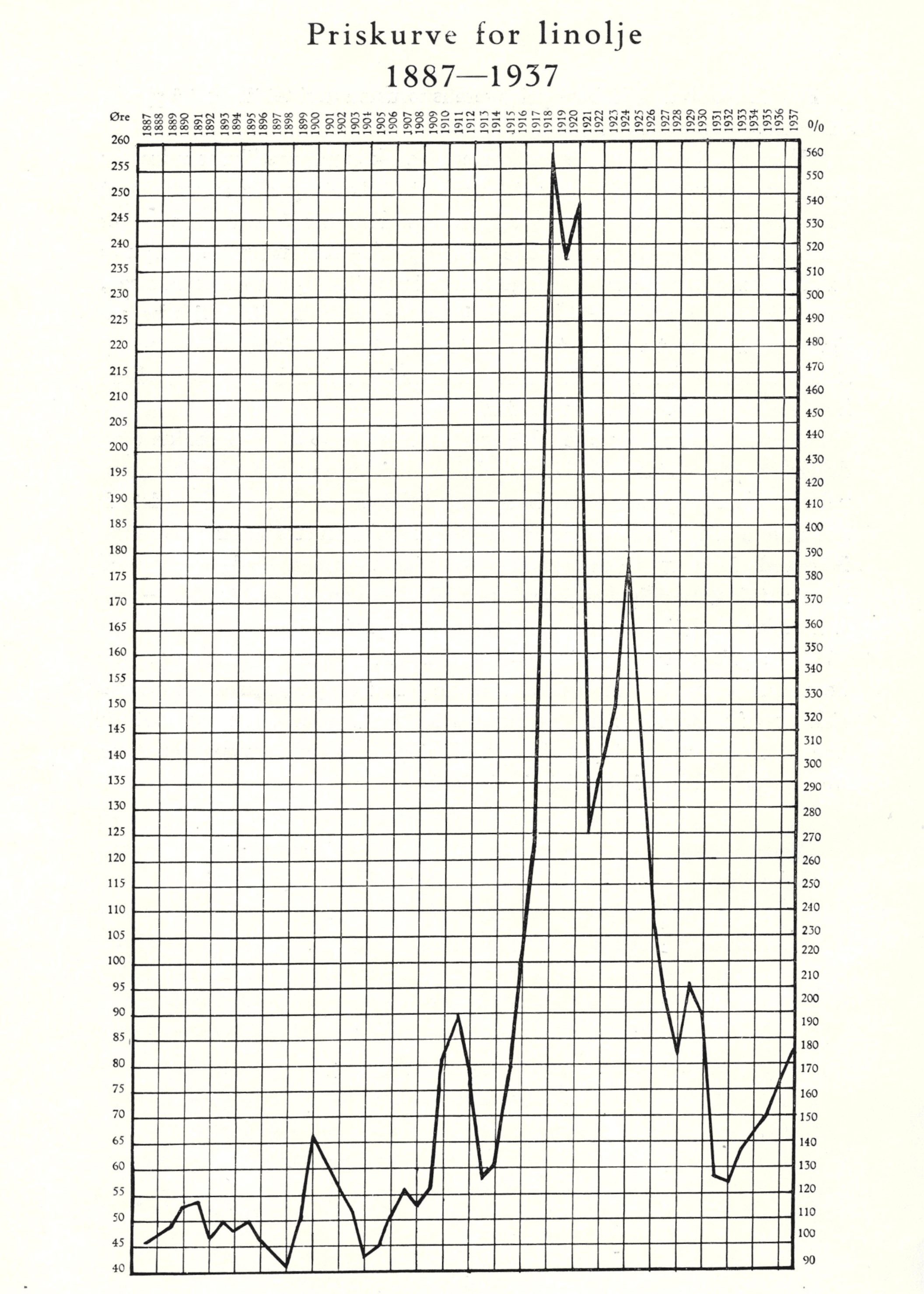

Linseed oil was the primary binding medium used in house paint and decorative paint for wood in the first half of the twentieth century in Norway. The cost of linseed oil rose dramatically during WWI (fig.1). In 1917, linseed oil was rationed and then became unavailable for commercial paint use. What were the consequences to restricted access to essential paint materials?

Preliminary results of an ongoing research project on painting materials in Norway during WW1 and post-war are presented in this poster. Maleren, a biweekly Norwegian journal for painters, paint traders and paint manufacturers, is the main primary source used.

The establishment of linseed oil regulations

The Norwegian Ministry of Industrial Supplies implemented regulations for the use of linseed oil for paint in 1917. As far as possible, only glue, limewash, casein paint and tar should be used, as well as emulsion paints and surrogate oils. Linseed oil was only permitted in the following circumstances:

- New woodwork, such as panels, doors, windows and floors, should be oiled only once in order to preserve the wood

- The flooring of old buildings should be oil painted only when absolutely necessary to preserve health and for home care purposes. The walls, ceilings, panels, doors and windows of old buildings should not be painted with oil

- Mural walls painted with water-based paint should not be repainted using oil paint

- Hospitals, and thereafter residential houses, should be given preference before other buildings for treatment with oil paint

How did painters adapt to the new circumstances?

The use of traditional paint recipes featuring available materials as animal and fish glue, fish liver oil, starch, flour and casein increased. Linseed oil residues were diluted with solvent or mixed with other binding media.

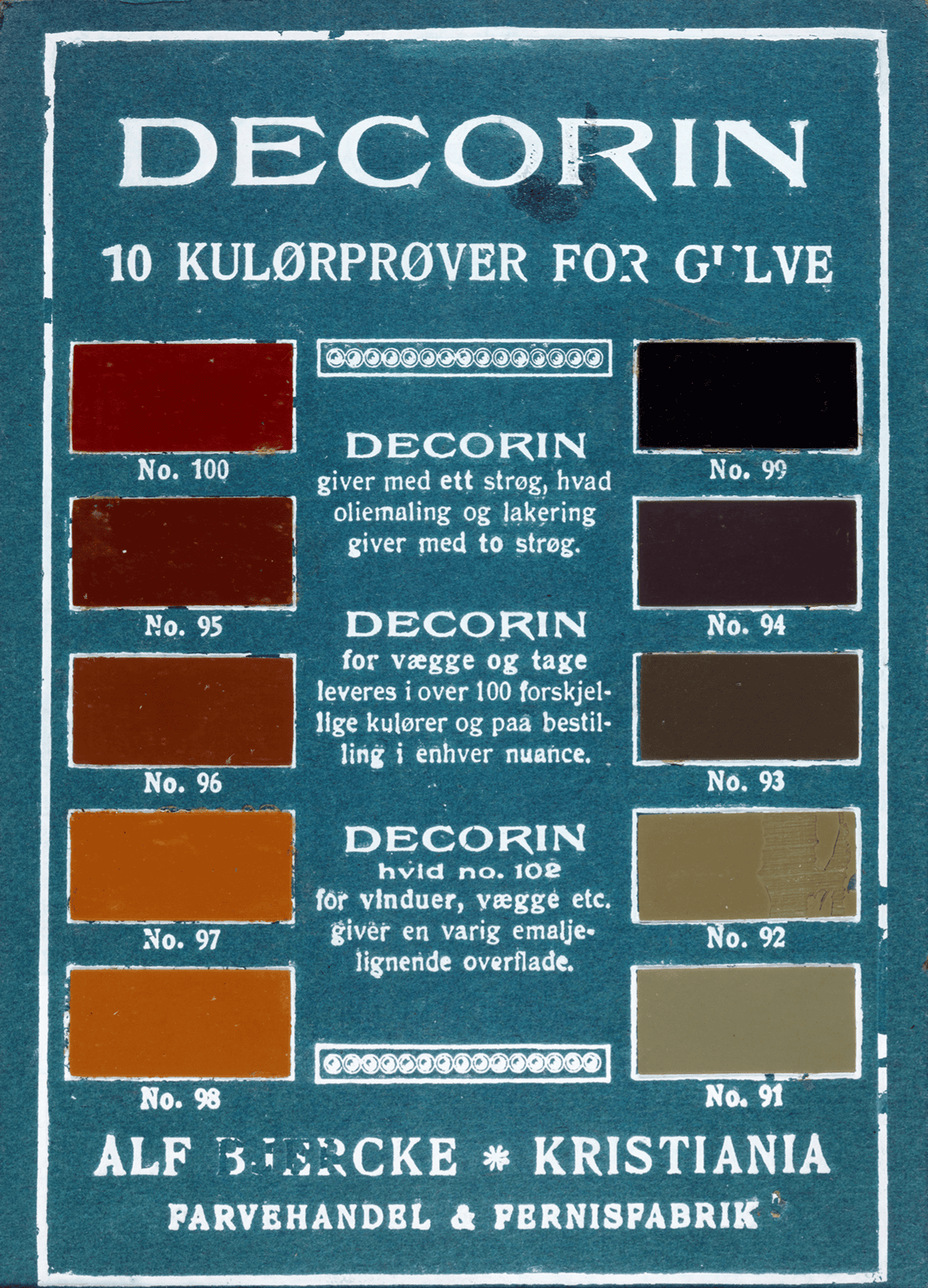

Ready-made enamel paint (fig.2) was recommended for surfaces that had to be washable. This was a deviation from the norm as the majority of painters in Norway mixed their own paint until the 1940-50s.

The use of “surrogate” products

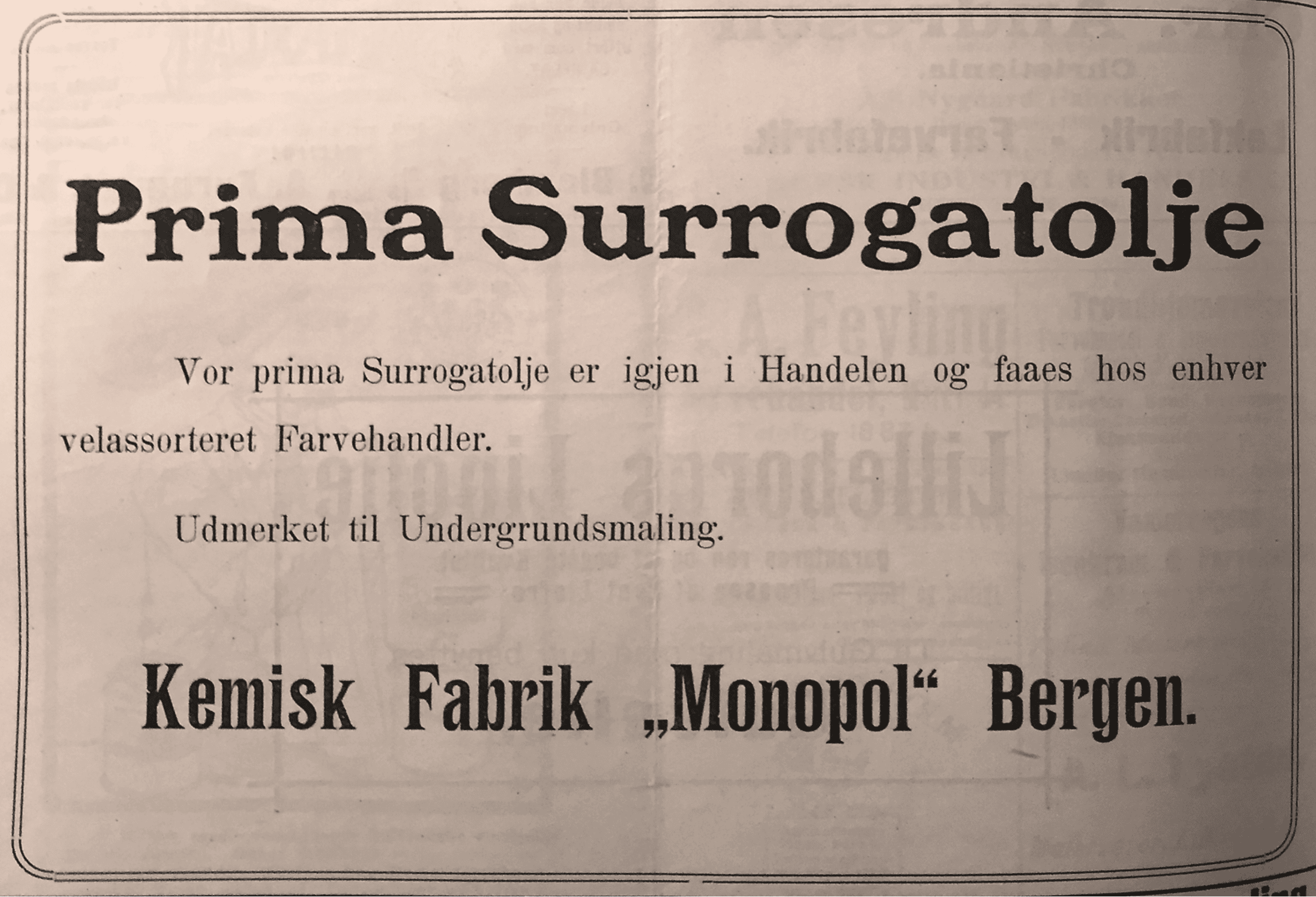

A variety of products labeled as “surrogate oil” and “surrogate paint”, Norwegian and imported, were frequently advertised in Maleren (fig.3). The content was not described, and the manufacturers often remained anonymous, perhaps to avoid repercussions owing to the poor quality of the products sold. A governmental committee named The surrogate committee was established in 1918 to conduct product tests and provide recommendations for the surrogate products.

Which materials were available at that time?

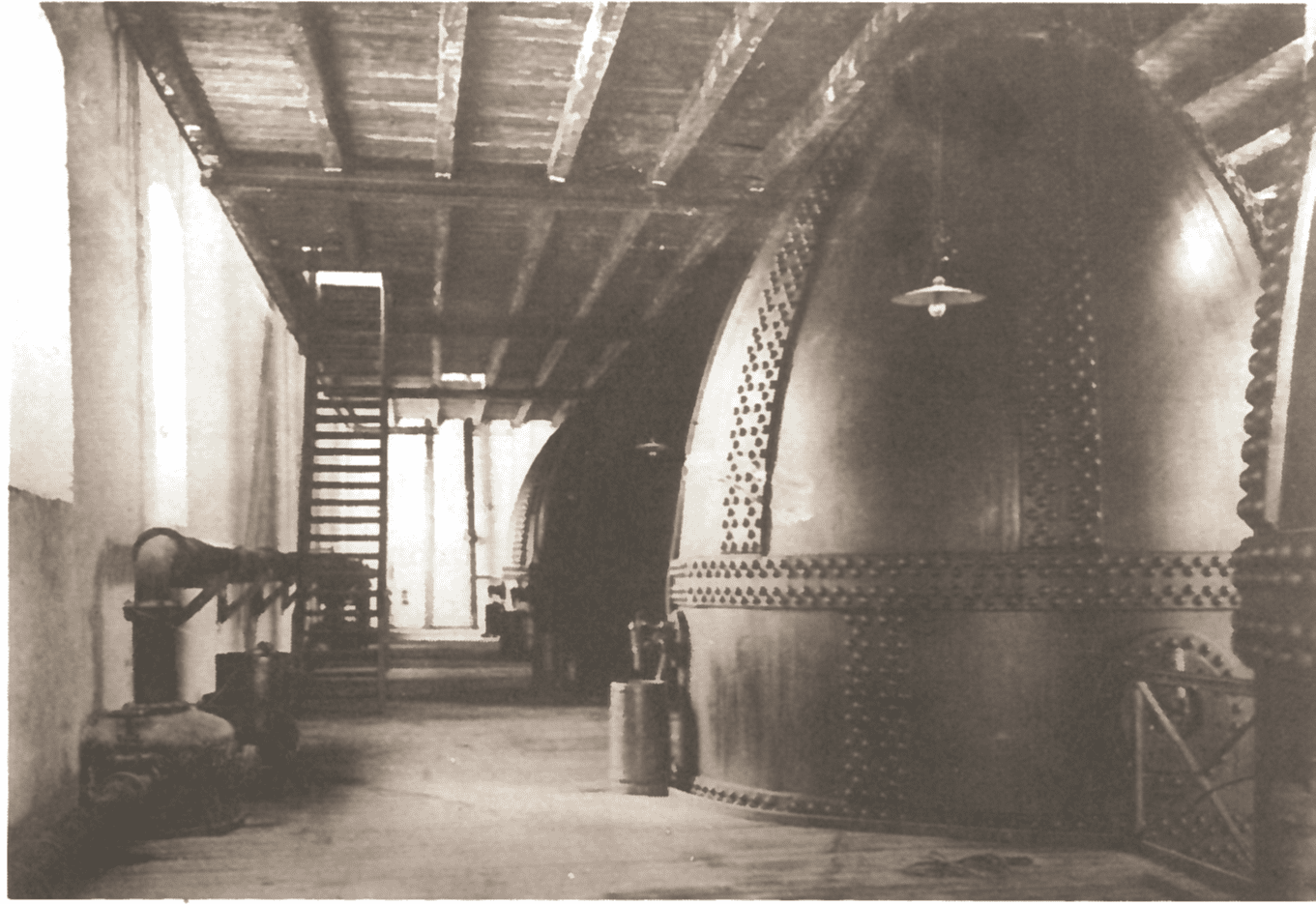

The need for binding media supplies inspired the creative application of local and national resources, including pulp and paper by-products. Large quantities of sulphite lye from the pulp and paper industry (fig.4) was readily available and cost-effective.

According to an article in Maleren “[…] most of the mentioned surrogate oils and paints are to a greater or lesser degree made of sulphite lye.” It is yet to be elucidated how the material was used. However, the undistilled lye must have comprised large quantities of wood turpentine, lignin and some pine resin.

Tung oil-containing paint products were also stocked. Alf Bjercke’s paint factory manufactured tung oil-based varnish for floors from 1899 (fig.5) and ready-made enamel paint from 1906 (fig.2) which is quite early within the international context. Hemp seed oil and sunflower oil were also marketed as binders in the Alf Bjercke’s paint factory`s list on oil varnishes in 1915.

Fish liver oil (cod, cusk, pollock and ling) could be sourced from industrial suppliers and probably also from small-scale local producers (fig.6). Its primary use as a binding medium was for outdoor paint. It could be used on its own or in combination with another oil, e.g., tung oil, or in emulsion paint.

Whale oil-based paint had been accessible to the market for some years prior to WW1. In 1917, famine fueled the revival of whaling along the Norwegian northern coast, which had previously been prohibited (fig.8). Accordingly, whale oil became available in 1918 for use as a component in oil-based paint. However, it is yet to be elucidated if whale oil-based paint was manufactured and used during and after WW1.

A binding medium was manufactured by processing alginate from kelp stalks, a large brown algae seaweed, by the scientist and industrial pioneer Axel Krefting. Alginate was first produced commercially on the Norwegian west coast during the war years, and the product was recommended as a binder for priming layers by a decorative painter in advertises in Maleren in 1921 (fig.7). However, the company went bankrupt. The industry of alginate didn`t have its break-through until the late 1920s, in the US.

Acknowledgements

Grateful thanks are extended to the Norwegian Research Council for the provision of funding.

Contact information

Paintings conservator/researcher

The Norwegian Institute for Cultural Heritage Research

Email: barbro.wedvik@niku.no